Marathon RJ-250 Self-Contained Compactor/Container

Compare a Marathon® RJ-250 compactor with any other self-contained compactor on the market, and you’ll quickly discover why Marathon® Equipment is the preferred choice of discriminating buyers. Marathon® Equipment is known throughout the world as one of the leading manufacturers of quality on-site waste compaction products. The RamJet® brand has been the industry standard for quality and innovation for more than 50 years and includes stationary and self-contained compactors, compaction containers, apartment, and high-rise compactors, pre-crushers, transfer systems, and a wide array of options for virtually any application.

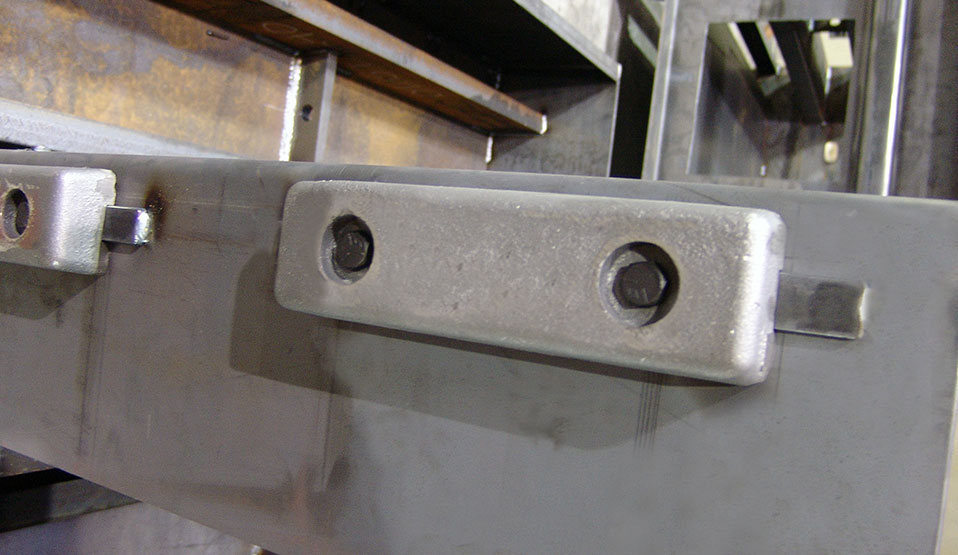

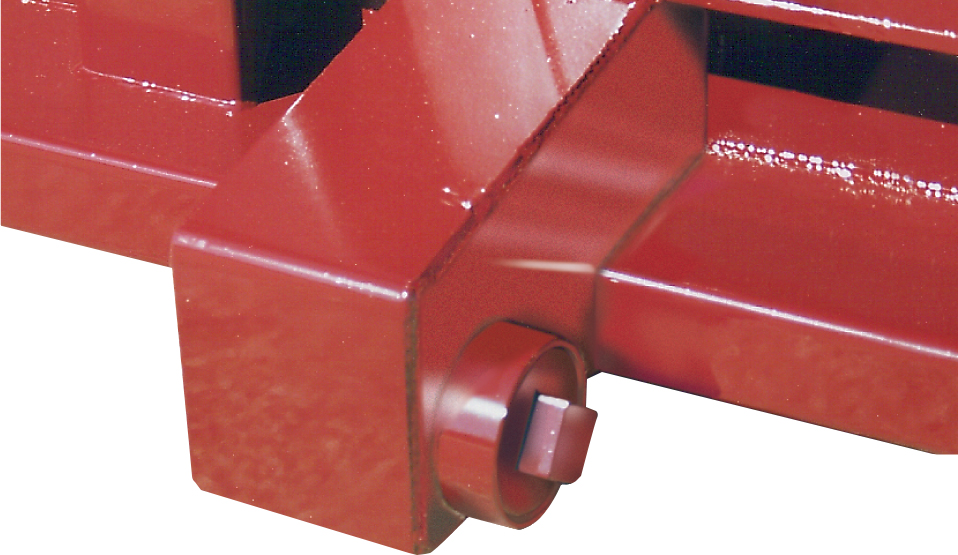

Marathon brand components are selected for longevity and minimum maintenance, with special attention given to the selection of high-duty cycle components. Stress engineering provides the optimum degree of structural integrity. Only the best materials are used, and the highest standards of quality are observed in the manufacturing process.

Our RamJet® units are state-of-the-art in roll-off self-contained compactors, featuring large feed openings, and expanded container storage capacity. They are designed to optimize safety for workers, store and transport your waste, prevent contamination of public areas in accordance with public health department requirements, improve working conditions for your employees, and reduce disposal costs.

The RJ-250SC compactor can be customized with a variety of loading arrangements to suit your specific needs.

- Exclusive 41″ x 58″ (1041mm x 1473mm) feed opening to handle large, bulky items

- Continuous feeding capability — even while the compactor is operating

- Adaptable to special loading systems such as large-capacity hoppers, security chutes, or total enclosures

- Odor and pest control from the Marathon® Ozone Odor Control option

- Easy loading from either ground or dock level

- Up to 24 tons (21,772 kg) of crushing force to reduce refuse to a fraction of its former size, saving valuable space and reducing landfill trips

- Fire hose connection provided on each unit

- Factory testing to ensure leak-proof construction

- StreamLine® Option – The StreamLine option enables excess liquid to be drained from the container, reducing net payload weight, and significantly reducing hauling costs. Liquid is routed to four interconnected 4″ (101.6 mm) drain outlets, located at each corner of the StreamLine unit. Connection can be made to a hose, piping, or a pump.

- Qwik Clean® Door – The Qwik Clean door on the packer end makes cleaning out behind the ram-in-cylinder area a snap. The door has miniature hinges, a door seal, and a ratchet binder. Also, featured is the RamJet rear feed doghouse door option.

All material on this page referring to Marathon RJ-250 Self-Contained Compactor/Container including text, images, logos and pdfs, are owned by Marathon, either through copyright or trademark, unless otherwise indicated.

Municipal Equipment, Inc. is an authorized Marathon reseller.